Create high-speed edge banding machine – double efficiency 0 line glue

Create high-speed edge banding machine – double efficiency 0 line glue

The main function:

Separation agent→Pre-milling→Infrared baking lamp→Fast sol*2→Servo gluing for gluing pot*2→Servo belt feeding→Servo pressing→Pneumatic leveling→Rough trimming→Fine trimming→Four-motor tracking→Edge scraping→ Flat scraping→cleaning agent→polishing*2

Equipment Highlights:

l lHigh-speed, high-stable edge banding machine with speed up to 30m/min

l lSelf-research department set 1: horizontal horizontal flush to solve the problem of knocking

l lSelf-developed set 2: Servo belt feeding

l lSelf-developed set 3: Press and paste with the same service

l lSelf-developed set 4: glue on the same clothes

Self-developed set: flexible servo belt

Driven by the same service motor, precise belt feeding

Structural optimization is more concise and maintenance is convenient

Self-developed set: Servo pressing

Oversized main pressing wheel, no tape

The main pressure roller adopts the yaw type design and the servo motor drive, and the pressing effect is better

Self-developed set: Servo coating

It is made of one-piece casting, the interior of the cavity is clean and smooth, and it is easy to clean the residual glue

Servo motor is precisely driven, automatically adjusts the amount of glue applied, reduces glue lines, avoids glue leakage, and saves glue

Self-research department set: level flush

Closed-loop control, no bumping, no bumping

Stable structure and easy maintenance

Double gluing pan

Double gluing design, equipped with two rapid sol systems, fast heating, high-precision gluing wheel ensures uniform gluing on various materials, and can be easily connected to the PUR function in the later stage.

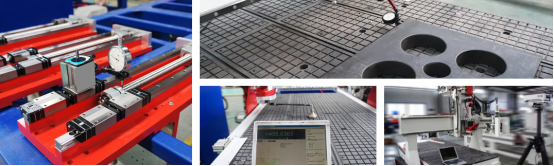

Pre-milled structure

With diamond pre-milling tool

Rough trim + fine trim structure

Four motors high-speed profiling tracking

scrape

Flat scraping wire breaking unit

A Committment to Excellence Excitech,a professional machinery manufacturing

company,was established with the most discriminating customers in mind. Your Needs,Our Driving Force We are committed to making your business a success by providing customized solutions necessary in achieving your goals.The seamless integration of our machineries with industrial automation software and system enhances our partners‘competitive advantages by helping them achieve:

Quality,Service and Customer Centric while Creating Unending Value

—–These are the Fundamentals of EXCITECH

Quality Defines Us

State-of-the-Art Products and Facilities

Our wide variety of readily available high quality portfolio includes Fully Automatic Smart Factory,Panel Furniture Production Solutions,Multi-Sized 5-axis

Machining Centers,Panel Saws,Point-to-Point Work Centers and other machineries dedicated to woodworking and other key applications.

Quality is never outsourced-The whole manufacturing process is meticulously and systematically controlled to achieve the guaranteed precision and quality.

•High quality products with the high production efficiency

•Lower costs thus measurable savings

•Shortened production time

•Maximized capacity for better profits

•Dramatically reduced cycle times